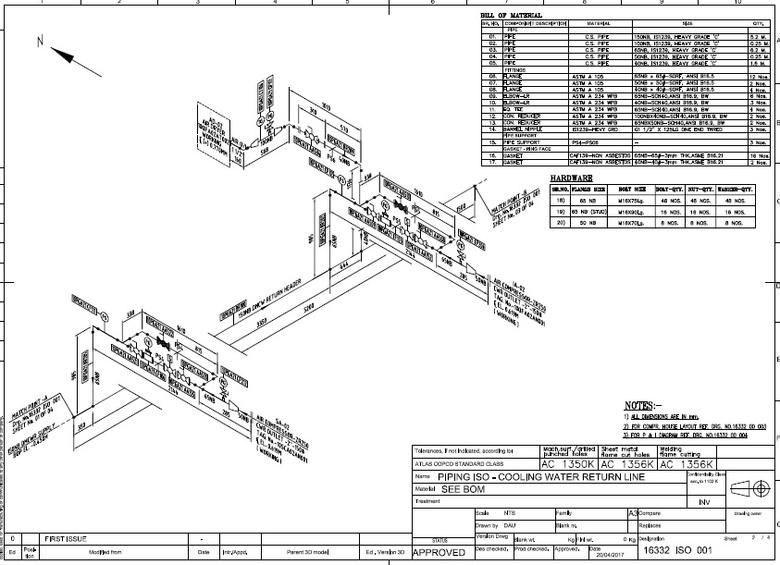

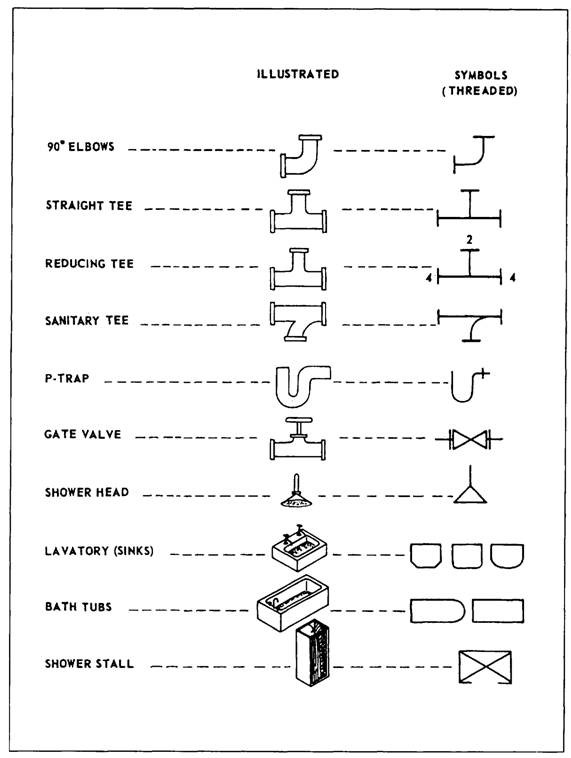

We are going to draw the figure shown on the right. Piping isometric drawing checklists | isometric checklist (with pdf) written by anup kumar dey. Click here to learn more details about Piping Isometric Drawings.Autocad provides some tools to aid us in creating the drawing, but not very many. By the Construction, the team to erect the piping items on the site following proper routing.Īll the above drawings are very important project documents and must be prepared with utmost thought and care to reduce the amount of rework at a later stage.By piping material group for purchasing materials.They are not to scale, single-line diagrams with symbols for pipe components, weld points, and supports. 5) represent the pipe routing with proper dimensions including all piping items and equipment. The total number of equipment to be erected in the plot.The exact location of equipment, buildings, roads, etc.Total area details of the process plant.A Plot plan provides the following information: The main purpose behind a plot plan layout drawing is to find the exact area available and how those spaces are used for piping, structure, and equipment positioning. Plot plant as a type of piping drawing is drawn in a to-the-scale drawing. PFD is important to easily understand any process, provide quality control, and increase efficiency. all critical valves including control valves.Ī process flow diagram explains relationships between major equipment of a plant and informs the fluid flow direction and connectivity between various equipment through the piping system.equipment capacity and basic operating information.and provide basic line lists parameters like pressure or temperature.list the equipment required for the plant.state the fluid material that is conveyed by the piping.2) is an un-scaled drawing or schematic which describes the process of transferring fluid inside the piping. Process Flow Diagrams (PFD)Ī PFD or Process Flow Diagram (Fig. Type of pipe supports required in the piping and pipeline systems.Correct positioning of the piping assembly on the pipe rack.Spacing or centreline distance between one pipe to the other line.

0 kommentar(er)

0 kommentar(er)